Glass fiber reinforced concrete gfrc panels are comprised of a 1 thick composite glass fiber concrete skin that is mechanically attached by flexible steel pins to a sturdy steel frame.

The ingredients for a gfrc wall panel.

Our concrete wall panels are cast using a glass fiber reinforced concrete gfrc matrix a high performance concrete that allows the panels to be made lighter stronger thinner and larger then conventional concrete.

Scratch coat brown coat and finish coat.

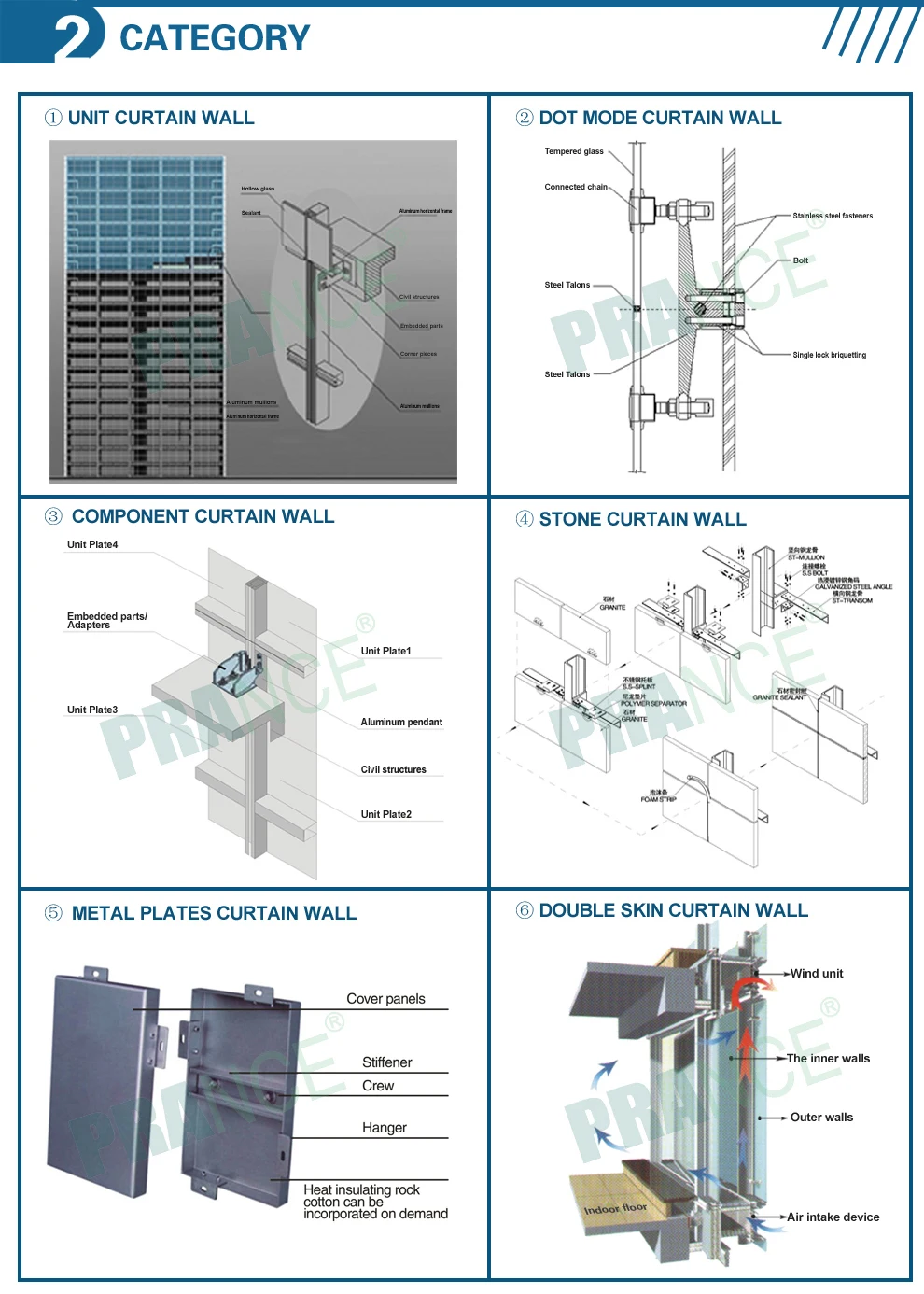

Gfrc panels wall cladding systems.

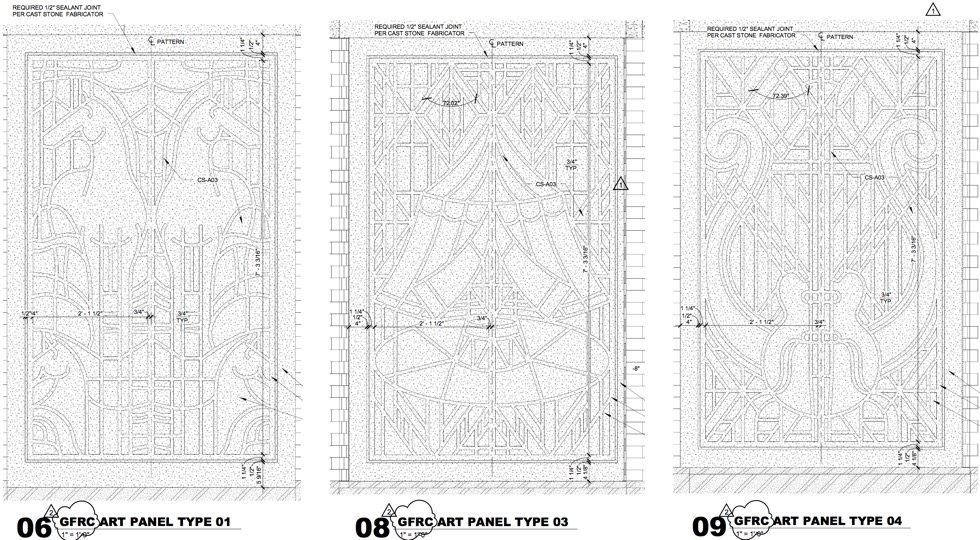

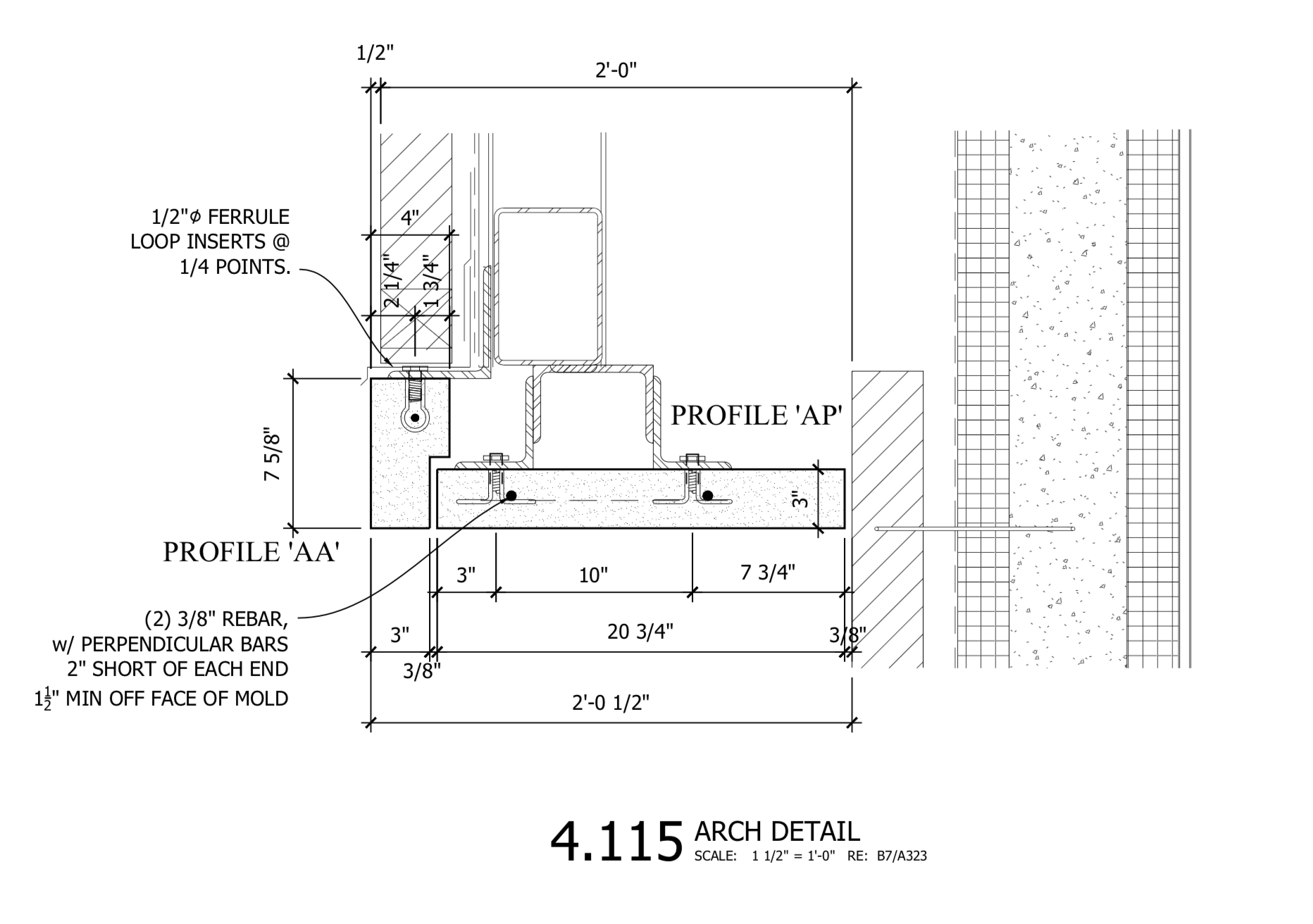

Black hawk example details.

Gfrc panels from gc products inc.

Gfrc panels allow for great aesthetic details and extensions such as cornices due to the manufacturing process.

Gfrc has quickly become the leading choice for exterior architectural designs.

The overall r values for the wall counting the gfrc panel and the interior air space exceed r19 and can be designed to r23 using 3 insulation.

On wood stud and cold formed steel stud wall assemblies stucco is typically applied in three coats.

Ameristar hotel black hawk co case study.

The glass fibers reinforce the concrete much as steel reinforcing bars do in conventional construction.

With its ability to withstand the elements light weight and outstanding customization capabilities gfrc is by far one of the top design materials for many.

Portland cement lime and sand.

Our gfrc wall panels are typically made at 3 4 1 thick.

In the first brandon details three different concrete mix recipes used in the casting of a gfrc bathroom counter with integral sink these are the face coat which is sprayed in to line the mold and does not contain fibers the vertical backing coat which is applied behind the face coat to the panel s upright surfaces and the self consolidating backing coat which fills.

Gfrc is similar to chopped fiberglass the kind used to form boat hulls and other complex three dimensional shapes although much weaker.

Unitized panel system drawing.

Cladding concepts is the proud united states partner for polycon brand glass fiber reinforced concrete.

Beginning from the first to the last the coats are generally called.

This face can be made with virtually any type of finish.

This material has advantages that are relevant for every type of design project.

It s made by combining a mixture of fine sand cement polymer usually an acrylic polymer water other admixtures and alkali resistant ar glass fibers.

Gfrc panels are an excellent choice for high rise buildings in areas of high seismic activity and for very decorative and intricate shapes and applications.

The polycon gfrc panel is a hand sprayed premixed high performance.